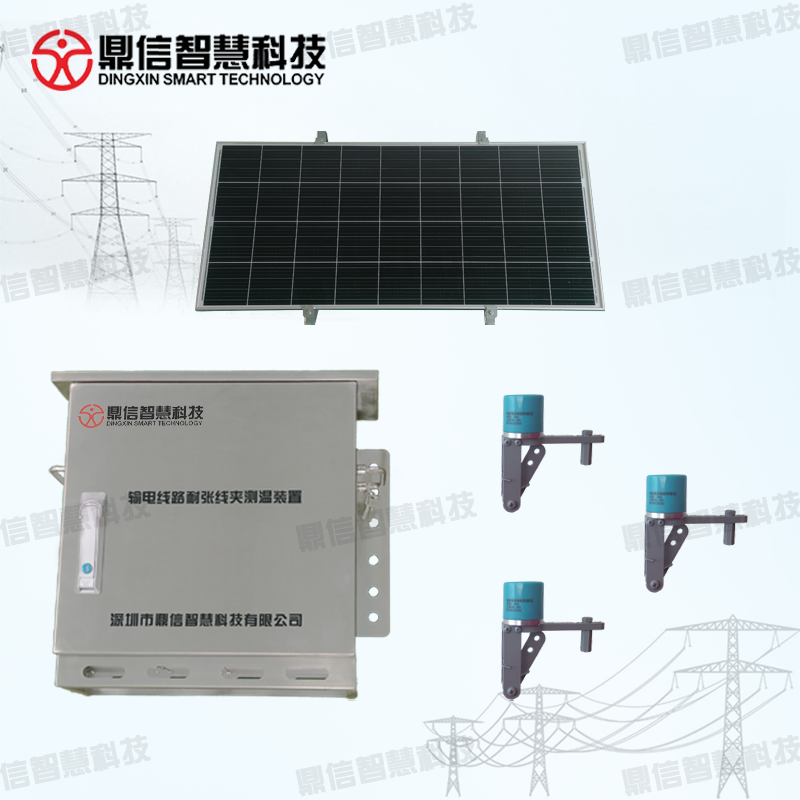

Temperature measuring device for strain clamp of transmission line

model:DX-WPS100-CW

1、 Demand analysis

At present, there is a serious shortage of electric power in China. The traditional capacity increasing technologies such as using heat-resistant conductors and improving the cross-sectional area of conductors have problems such as long construction period, difficult acquisition of transmission corridors, and high cost. Starting from the relationship between the conductor temperature and the current carrying capacity of the transmission line, the online temperature monitoring device for the transmission line clamp is proposed based on the theoretical model of dynamic capacity increase of the transmission line based on the operating temperature of the conductor and the clamp. The temperature measuring device adopts the electric field energy collection technology combined with the battery power supply, which solves the problem of difficult power supply for the temperature measuring device, The wire temperature hosts can support the access of multi probe temperature data, provide decision-making basis for the capacity increase of transmission lines, and ensure the stable operation of lines.

2、 Working principle

The online temperature monitoring device of transmission line clamp adopts the Internet of Things technology to monitor the working temperature of the tension tower joint, so as to prevent the tension clamp from being damaged by thermal stress due to factors such as construction technology, material, overload and loose connecting plate bolts, which will eventually lead to accidents. The host computer sends the temperature data collected by the clamp temperature sensor to the monitoring center through the 4G/5G/WIFI wireless network after digitization and compression coding, decodes the data signal in the monitoring center, and visually displays the wire temperature data on the screen in the form of figures and charts. When the temperature exceeds the set threshold, the alarm will be started immediately, and the management personnel will notify the maintenance personnel to deal with it in time to ensure the stable operation of the line.

3、 Product features

(1) Basic configuration of clamp temperature measurement: main control unit, clamp temperature measurement unit, communication unit, power supply unit, mounting bracket and auxiliary materials;

(2) It can sense and collect the wire surface temperature and wire fitting temperature for corresponding storage, and transmit the measurement results to the monitoring center through the communication network, supporting multi-channel temperature data access;

(3) Automatic collection function: automatically collect the temperature of wires and fittings according to the set time interval. The small collection interval is less than 2 minutes, and the collection interval is not more than 40 minutes. The default collection interval is 10 minutes.

(4) Real time monitoring of the surface temperature of line clamp hardware, corresponding storage, and transmission of the measurement results to the data concentrator or data processing system through the communication network.

(5) On line temperature acquisition unit has power supply voltage, working temperature and other acquisition functions.

(6) The electric field energy collection plus battery integrated power supply mode shall be adopted, and the structure shall be reliable and practical.

(7) The shell and conductor adopt equipotential design to ensure that the temperature measuring device is not interfered by the line.

(8) The primary calculation function of the original collected quantity can obtain the state quantity data that can directly reflect the temperature.

(9) The ability to modify the acquisition frequency, sampling interval, network adapter address and other parameters according to remote instructions;

(10) It can encrypt the data and access the intranet platform of provincial companies.

(11) It can monitor and display the temperature status trend of the temperature measuring point in real time, display the data in multiple ways, analyze the data, and generate reports for display.

(12) At least 3 temperature monitoring limits shall be set, including early warning temperature value, alarm temperature value and over limit temperature value, and the set limit value can be changed according to user requirements.

(13) The system can run on multiple platforms. The system should be released in the way of WEB terminal, and have the real-time viewing function of mobile APP.

4、 Technical parameters

Serial No | category | project | technical parameter |

1 | Overall performance | Complete machine configuration | 主控单元、线夹测温单元、通信单元、供电单元、安装支架及辅材 |

2 | Overall quality | 小于30KG(含太阳能板和支架) | |

3 | texture of material | 不锈钢机身+热镀锌支架 | |

4 | Clamp temperature measuring unit | Communication frequency | 2.4GHz~2.5GHz |

5 | Temperature measurement range | -40℃~+125℃; | |

6 | Temperature measurement accuracy | ±1℃; | |

7 | Long measurement cycle | 30s | |

8 | Operating current | Quiescent sleep current:<9uA(3.6V,25℃),Peak value of operating current:<11mA, (3.6V,25℃) | |

9 | Overall dimensions | ≤φ57 X22H mm | |

10 | Communication unit | communication mode | All Netcom 4G/5G/WIFI wireless transmission |

11 | Data security | VPN dedicated channel can be used for communication with the master station, and encryption transmission is optional. | |

12 | Access protocol | Access to monitoring platforms of provincial power companies such as Southern Power Grid and State Grid | |

13 | Power supply unit | Battery capacity | 60Ah/12V |

14 | Solar panel power | 100W/18V | |

15 | Power supply duration | The power supply requirement that the device can operate normally for 15 days without continuous illumination. | |

16 | Other parameters | work environment | working temperature:-40~+70℃;relative humidity:5~99%RH |

17 | Overall service life | More than 8 years | |

18 | Degree of protection | IP67 |