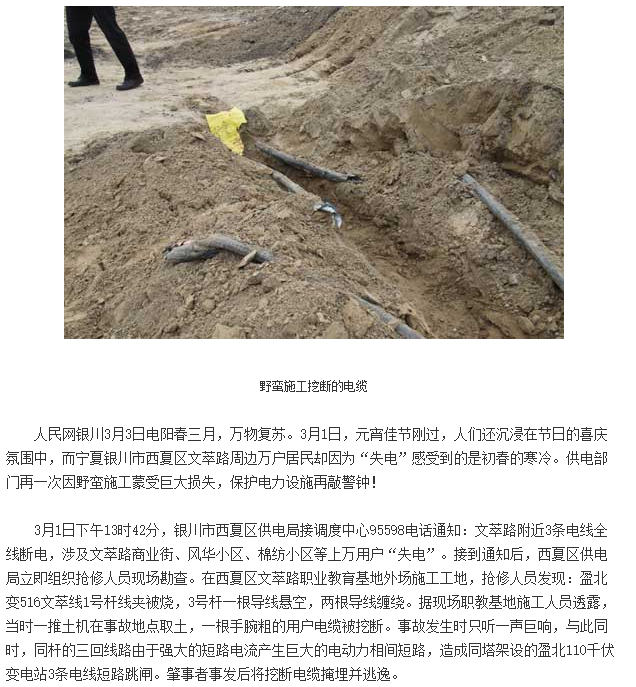

Underground pipelines are an important part of urban infrastructure, including a variety of pipelines for electricity, communications, gas, water supply and drainage. Due to the complexity of underground space and the density of pipelines, mechanical construction, excavation and other operations during road, subway and municipal construction are likely to cause damage to underground cable pipelines, leading to power outages and other problems, and are not easily repaired.

Many accident cases have shown that the main cause of underground pipeline breakage is the influence of external forces. Whether it is road construction or subway construction, the use of heavy machinery and ground vibration may cause damage to the fragile power pipelines. Especially those pipelines that are old and made of aging materials, it is even more difficult to withstand such tremendous pressure and impact.

In the face of this problem, how can we sit back and do nothing? On the one hand, improving the management level of the construction site is the key to reducing pipeline breakage. This includes adequate geological investigation before construction to ensure that the specific location and status of all underground pipelines are understood; excavation techniques used in construction to avoid harm to pipelines caused by blind operations; and, at the same time, strengthening on-site supervision to ensure that all operations comply with the norms and reduce the damage caused by human error.

On the other hand, the use of modernized materials and technologies, such as corrosion-resistant and pressure-resistant pipes, can substantially improve the service life and risk resistance of pipelines. In addition, the introduction of intelligent monitoring systems to monitor the operating status of pipelines in real time, and to deal with anomalies as soon as they are found, can prevent accidents from occurring to a large extent, which is what we are going to talk about today - Intelligent Ground Spike, also known as the underground cable anti-exterior breakage of the ground spike.

Shenzhen Dingxin Intelligent Technology DX-DLS100-B2 type intelligent ground nail, intelligent ground nail by the intelligent analysis module, gyroscope sensors, wireless module, backup battery, solar panels, metal protective shell, Beidou positioning and sound and light alarms and other components, installed in the buried line above the surface (flush with the road surface), it can be a real-time monitoring of more than a dozen meters around the scope of the abnormal vibration frequency, autonomous It can monitor the frequency of abnormal vibration in a range of more than ten meters around in real time, independently study and judge whether there is large-scale construction work near the underground cable, and send information such as the warning location and the name of the ground nail in real time to the cable intelligent monitoring platform and WeChat of the operation and maintenance personnel, and the operation and maintenance personnel can go to the address of the accident quickly through the built-in navigation to confirm and deal with it.

Ltd., long-term commitment to transmission line online monitoring, distribution line online monitoring, substation integrated detection, cable online monitoring, distributed fault diagnosis, distribution network traveling wave fault warning and positioning, high-voltage anti-external breakage warning, vehicle electrocution early warning, Beidou positioning monitoring equipment research and development, production, sales, technology maturity, qualification, to meet the requirements of the bidding, in all parts of the world are Installation]