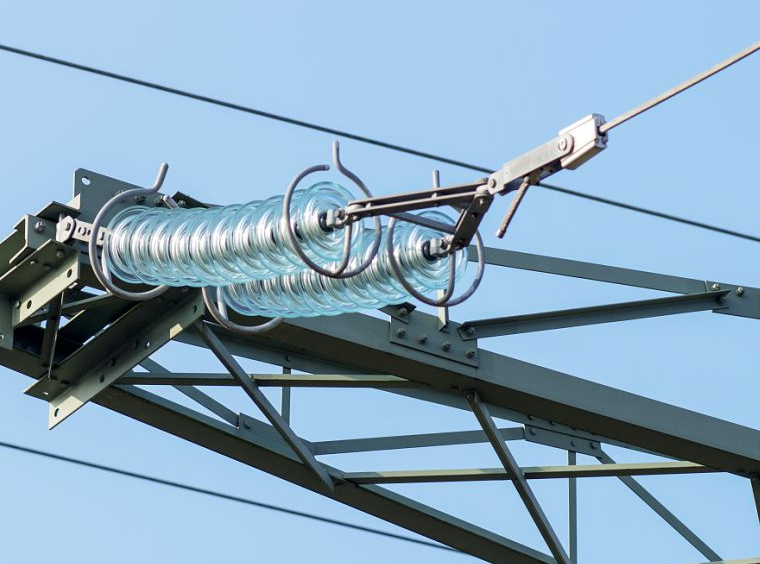

In modern power systems, power lines are important hubs connecting generating stations to consumers. However, such power lines face a variety of trials and tribulations during long-term operation, especially during peak power periods. Among them, problems such as high-temperature heating of connector wire clips, loose wire clips, and fixing bolts that do not meet the standards at the time of commissioning have become important hidden dangers for the efficient operation of power supply systems. Especially during the peak period of electricity consumption in hot weather, the elevated pressure of power supply further aggravates the severity of this problem, which may also lead to tripping in serious cases.

When the temperature of the joints exceeds the acceptable temperature of the power line, it can lead to overheating or even fire of the joints, which can lead to large-scale power outages in the power supply system. This not only leads to unchanged daily life for the public, but also leads to important economic losses and social effects. Thus, it is important to effectively monitor and manage the temperature of line line clamps.

Currently, there are a very limited number of manufacturers in China that can perform power line clamp temperature measurement. This is generally determined by the uniqueness of the high-voltage experimental environment. In this context, Shenzhen Dingxin Wisdom Technology on-line breakthrough power line temperature online monitoring device, to solve this problem provides effective service guarantee.

The core of the device is the wire clip temperature measurement sensor, it can collect the temperature data through the data compression coding, and then according to the 4G/5G/WIFI network timely transmission to the monitoring system. In the monitoring system, the wire, clamps, fittings and other locations of the temperature data through the figures and charts directly on the screen, but also to provide over-temperature warning that the hidden danger of information issued to remind, to ensure that the power personnel can real-time grasp of the operation of the power line, and immediately found anomalies and rushed to the scene to confirm, deal with.