Transmission line operation and maintenance is a complex and critical task, today, Shenzhen Dinsee smart Technology Co., Ltd. to analyze the transmission line operation and maintenance pain points and solutions.

spot analysis

1, transmission lines usually cross lofty mountains and steep hills, with a wide geographical coverage and a length that may reach hundreds or even thousands of kilometers, making the operation difficult and requiring the investment of large amounts of human and material resources.

2. affected by weather and natural disasters, such as lightning strikes, typhoons, earthquakes, etc. These natural factors can damage line equipment and lead to line failures, bringing additional difficulties to line operation and maintenance.

3, the traditional transmission line operation and maintenance mainly relies on manual inspection and regular maintenance, and this method can not detect line faults or potential problems in a timely manner. The lack of real-time monitoring and early warning mechanisms makes it difficult to troubleshoot and repair line faults, increasing maintenance time and costs.

4, part of the monitoring device used on the line with a single function, the information integration is not high, can not comprehensively monitor the line operation status, can not provide effective decision-making basis for line operation and maintenance.

prescription

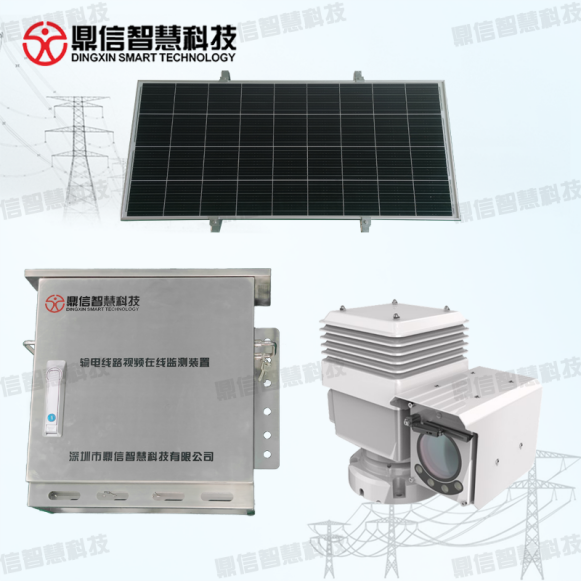

In order to overcome these difficulties, it is necessary to introduce new technologies and methods to improve the efficiency and quality of line operation and maintenance. Shenzhen Dinsee smart Technology Co., Ltd. transmission line image video online monitoring device (dual-light dome) DX-WPS100-SP2, using "dual-light infrared video + visible light video" monitoring mode, through the wireless network and monitoring center for data interaction, can realize the tower status, metal tools, insulator strings, conductors and channels and other details of all-round status detection. It can realize all-round status detection of the tower status, metal tools, insulator strings, conductors and channels, etc., and guarantee the stable operation of the line.

Functional characteristics of double optical dome

1, 24h HD panoramic monitoring: the cloud billiard dome is equipped with high-definition dual-camera, main camera 1600w pixels, secondary camera 200w pixels, illuminance 0.001Lux, support for night vision full-color shooting, can be rotated horizontally 360 ° rotation, vertical -90 ° ~ +90 ° rotation, 24 hours of 360 ° monitoring line.

2, thermal imaging monitoring: the use of thermal imaging lens, through a non-contact way, the temperature of the power equipment can be monitored, timely detection of abnormal heat and thermal defects in power equipment, and make early warning.

3, wide-angle picture-in-picture: support visible light and thermal imaging picture-in-picture and image fusion, 40 times optical zoom, can observe a wide range of visual range, to achieve the channel, tower, neighboring towers, the surrounding environment and other global image monitoring.

4, the risk of intelligent identification: based on the industry's depth of customized intelligent analysis algorithms, support for picture capture analysis, AI target identification function, can intelligently identify the line outside the broken, defective insulator fittings broken, fire and other risks, real-time early warning.